Good maintenance practices are critical to keeping aircraft in top shape. EASA 66 Module 7 will instruct the student in the proper practices of everything from safety in the workshop to what to do after an abnormal event.

- 7.1 Safety Precautions -

- Aspects of safe working practices including precautions to take when working with electricity,gases especially oxygen, oils and chemicals. Also,instruction in the remedial action to be taken in the event of a fire or another accident with one or more of these hazards including knowledge of extinguishing agents.

Aircraft and Workshop

- 7.2 Workshop Practices

- Care of tools, control of tools, use of workshop materials; Dimensions, allowances and tolerances,standards of workmanship; Calibration of tools and equipment, calibration standards.

- 7.3 Tools

- Common hand tool types;Common power tool types;Operation and use of precision measuring tools;Lubrication equipment and methods;Operation, function and use of electrical general test equipment.

- 7.4 Avionic General Test Equipment

- Operation, function and use of avionic general test equipment

- 7.5 Engineering Drawings, Diagrams and Standards

- Drawing types and diagrams, their symbols,dimensions, tolerances and projections;Identifying title block information;Microfilm, microfiche & computerized presentations;Specification 100 of the Air Transport Association (ATA) of America;Aeronautical and other applicable standards including ISO, AN, MS, NAS and MIL;Wiring diagrams and schematic diagrams.

- 7.6 Fits and Clearances

- Common system of fits and clearances;Schedule of fits and clearances for aircraft and engines;Limits for bow, twist and wear;Standard methods for checking shafts, bearings and other parts.

- 7.7 Electrical Cables and Connectors

- Continuity, insulation and bonding techniques and testing;Use of crimp tools: hand and hydraulic operated;Testing of crimp joints;Connector pin removal and insertion;Coaxial cables: testing and installation precautions;Wiring protection techniques: Cable looming and loom support, cable clamps, protective sleeving techniques including heat shrink wrapping, shielding.

- 7.8 Riveting

- Riveted joints, rivet spacing and pitch; Tools used for riveting and dimpling; Inspection of riveted joints.

- 7.9 Pipes and Hoses

- Bending and belling/flaring aircraft pipes; Inspection and testing of aircraft pipes and hoses; Installation and clamping of pipes.

- 7.10 Springs

- Inspection and testing of springs.

- 7.11 Bearings

- Testing, cleaning and inspection of bearings; Lubrication requirements of bearings; Defects in bearings and their causes.

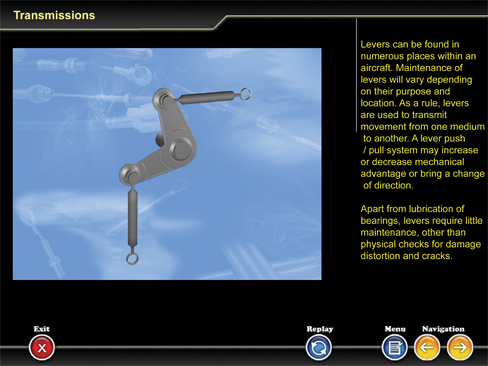

- 7.12 Transmissions

- Inspection of gears, backlash;Inspection of belts and pulleys, chains and sprockets;Inspection of screw jacks, lever devices, push -pull rod systems.

- 7.13 Control Cables

- Swaging of end fittings; Inspection and testing of control cables; Bowden cables; aircraft flexible control systems.

- 7.14 Material Handling

- Sheet Metal Marking out and calculation of bend allowance;Sheet metal working, including bending and forming;Inspection of sheet metal work.Composite and non-metallic bonding practices;Environmental conditions;Inspection methods.

- 7.15 Welding, Brazing, Soldering and Bonding

- (a)- Soldering methods; inspection of soldered joints;

- (b)- Welding and brazing methods;

- Inspection of welded and brazed joints;Bonding methods and inspection of bonded joints.

- 7.16 Aircraft Weight and Balance

- (a)- Centre of Gravity / Balance limits calculation: use of relevant documents;

- (b)- Preparation of aircraft for weighing;

- 7.17 Aircraft Handling and Storage

- Aircraft taxiing / towing and associated safety precautions;Aircraft jacking, chocking, securing and associated safety precautions;Aircraft storage methods;Re-fuelling / de-fuelling procedures;De -icing/anti -icing procedures;Electrical, hydraulic and pneumatic ground supplies;Effects of environmental conditions on aircraft handling and operation.

- 7.18 Disassembly, Inspection, Repair and Assembly Techniques

- (a)- Types of defects and visual inspection techniques;Corrosion removal, assessment and re-protection.

- (b)- General repair methods, Structural Repair Manual;Ageing, fatigue and corrosion control programs

- (c)- Non destructive inspection techniques including, penetrant, radiographic, eddy current, ultrasonic and boroscope methods.

- (d)- Disassembly and re -assembly techniques.

- (e)- Trouble shooting techniques.

- 7.19 Abnormal Events

- (a)- Inspections following lightning strikes and HIRF penetration.

- (b)- Inspections following abnormal events such as heavy landings and flight through turbulence.

- 7.20 Maintenance Procedures

- Maintenance planning;Modification procedures;Stores procedures;Certification/release procedures;Interface with aircraft operation;Maintenance Inspection/Quality Control/Quality Assurance;Additional maintenance procedures;Control of life limited components.